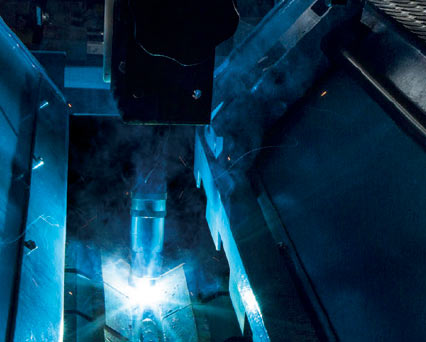

The shielding gas you use when welding has a great impact on your final product quality. Inconsistencies in the shielding gas can lead to issues like spatter, oxidation and weld defects. Additionally, selecting the right shielding gas to use can be time-consuming and confusing with complex offers that include too many options. With five ready-to-weld pure argon and argon gas mixtures exceeding AWS A5.32/ISO 14175 tolerance requirements, ARCAL simplifies shielding gas selection and provides you with the high quality gas you need to produce better welds. And unlike other shielding gases, ARCAL puts an end to wasted gas, time and money while minimizing safety risks. ARCAL shielding gases also come in multiple supply modes to accommodate your needs.

Contact an expert

Or call (800) 909-8058 to place an order for ARCAL™ with SMARTOP™ or EXELTOP™.

An Airgas expert will be in touch to discuss reliable supply and services for advanced battery and energy storage.

What are your challenges?

Our concise ARCAL Reference line consists of five ready-to-weld pure argon and argon welding gas mixtures. ARCAL offers unmatched simplicity, performance, reliability and consistency in each of our five expertly-designed gases — derived from the research gained from over 400 welding trials — whether your gases are mixed on-site or delivered.

ARCAL Prime The Pure Solution |

ARCAL Chrome The Brilliant Choice |

ARCAL Speed Productivity Plus |

ARCAL Force Powerful Force |

ARCAL Flux Consistent Results |

|

|---|---|---|---|---|---|

| SHOP ARCAL Prime | SHOP ARCAL Chrome | SHOP ARCAL Speed | SHOP ARCAL Force | SHOP ARCAL Flux | |

| Composition | 99.998% Ar | 98% Ar / 2% CO2 | 92% Ar / 8% CO2 | 82% Ar / 18% CO2 | 75% Ar / 25% CO2 |

| Process & Materials |

GTAW & PAW

GMAW

Additive Manufacturing

|

GMAW

GMAW

Additive Manufacturing

|

GMAW & MCAW

|

GMAW & MCAW

Additive Manufacturing

|

FCAW & MCAW

GMAW Solid Wire

|

| Features |

|

|

|

|

|

| SHOP ALL ARCAL GASES |

When your application requires a special blend with tight specifications, our ARCAL Technical line offers customized, consistent and high-performance welding gas mixtures.

With the support of more than 60 Advanced Fabrication experts, we’ll help you find the mix that best suits your needs. Contact an expert

ARCAL is available in cylinders equipped with SMARTOP™ or EXELTOP™, cylinder packs or liquid form. We provide ARCAL and other shielding gases for welding in a range of supply modes designed for quality, safety, consistency and ease of use for any consumption needs.

ARCAL Shielding Gases

No matter which ARCAL product you choose, get the highest quality and most consistent welding gas you need, every time.

Download the Brochure

ARCAL Prime

Read about our high-quality, high-purity 99.998% argon for TIG (GTAW) and plasma welding, MIG (GMAW) welding and universal root shielding.

Download the Brochure

ARCAL Chrome

Learn about our 98/2 Ar/CO2 welding gas mixture for all stainless steel MIG (GMAW) welding.

Download the Brochure

ARCAL Speed

Discover our expertly mixed 92/8 Ar/CO2 welding gas perfect for automated and robotic applications with high travel speed and deposition rates.

Download the Brochure

ARCAL Force

Find out more about our powerful ready-to-weld 82/18 Ar/CO2 mixture for MIG welding of heavy carbon steel structures.

Download the Brochure

ARCAL Flux

Explore our all-purpose 75/25 Ar/CO2 welding gas mixture designed specifically for FCAW, MCAW and MIG (GMAW).

Download the Brochure

jM Process Solutions

See how ARCAL helps keep jM Process Solutions ahead of the game.

Watch the Video

U.S. Fittings

See how ARCAL helps U.S. Fittings, Inc. deliver the quality their customers expect.

Watch the Video

The RADNOR™ made by 3M™ Speedglas™ professional‑grade welding helmet